ADDRESSING ENVIRONMENTAL ISSUES FOR A DRY CLEANING BUSINESS CAN GET EXPENSIVE. TO HELP DEFRAY THE COST, SOME STATES HAVE CLEANUP TRUST FUNDS FOR DRY CLEANERS TO PAY INTO AND EVENTUALLY USE. AS OF NOVEMBER 2019, THOSE STATES ARE ALABAMA, CONNECTICUT, ILLINOIS, FLORIDA, KANSAS, NORTH CAROLINA, OREGON, SOUTH CAROLINA, TENNESSEE, TEXAS, AND WISCONSIN.

BY: DRU CARLISLE

While it would be ideal to rely on these funds alone to pay for necessary investigation and remediation services, it’s not always the most viable option because while there are certainly strong funds still in operation, we have seen that some funds are considering sunsetting, and with others, reimbursement payments are being delayed.

Another or additional solution for dry cleaners is to track down their historical Commercial General Liability (CGL) insurance policies. By locating these policies, a dry cleaner can use them as assets (money) to help cover the costs associated with environmental investigations and cleanups, such as investigation, remediation, and legal fees. We’ve been assisting dry cleaners in states with and without trust funds through this process for over two decades.

Here are some common questions we hear from the dry cleaning community about state cleanup funds.

1. WHAT CAN DRY CLEANERS IN STATES WITHOUT ADEQUATE CLEANUP FUNDS DO TO GET HELP WITH FUNDING THEIR CLEANUPS?

The first thing that a dry cleaner should do is look for all of their old insurance policies. Typically, the older the policy, the fewer restrictions they have regarding covering environmental contamination claims. Generally, we need policies that were issued before 1985. Dry cleaners should look through all old bank records, and write down the name and company of all insurance brokers they have worked with. Secondly, they should jot down a history of when they started at the location, who they purchased insurance from, what types of stores were at that location (or adjacent) and what other insurance was part of the property. They will also need to identify whether or not there was a previous dry cleaner who may have caused or contributed to contamination. Finally, we recommend not moving forward without expert advice. Often times if a dry cleaner launches into a cleanup without notifying insurance carrier(s), they will not be reimbursed for money spent on the site investigation and cleanup.

2. WHY ARE INSURANCE CLAIMS SO SIGNIFICANT IN TRIGGERING INSURANCE COVERAGE?

Making a valid claim to your carrier can mean the difference between paying hundreds of thousands of dollars for a site cleanup compared to paying a small amount for startup costs like. In most instances, a valid claim made to an insurance company will be defended. Among other things, this defense can include legal fees and site investigation activities.

3. SHOULD A DRY CLEANER PAY OUT-OF-POCKET EXPENSES FOR A CLEANUP THEN LATER TENDER A CLAIM TO RECOVER THAT LOSS OF EXPENSES?

Depending on the state, it is common for an insurance carrier to decline paying costs incurred before a claim was tendered. We have had several clients that spent money on investigations and cleanups, but were only reimbursed a fraction of their costs because the insurance carriers felt they could have managed the work differently and cheaper.

4. IF A DRY CLEANER IS WAITLISTED FOR A CLEANUP FUND, CAN HE OR SHE PROCEED WITH THE SALE OF THE BUSINESS? WILL THE VALUE OF HIS OR HER BUSINESS BE ADEQUATELY PROTECTED?

In many states that have cleanup funds, a prospective purchaser agreement (PPA) will allow a property transaction to proceed prior to a regulatory release and sign off of no further action. However, a PPA generally does not remove any contingent liabilities associated with the dry cleaning site; but instead delays the inevitable site investigation and potential cleanup. It also allows the purchaser more time to discover any additional problems that the seller’s are often responsible for.

Furthermore, the involvement of a dry cleaner in a fund does not remove any contingent environmental liabilities from the site itself, nor does it fully protect the dry cleaner from any potential actions that might arise from contamination. These issues could include diminished values to property or to other properties that might be affected by contamination coming from the site. Also, the cleanup funds do not fully protect a dry cleaner from a citizen or third party suit associated with contamination coming from his/her site.

Learn how to sell your dry cleaning business in three steps

5. HOW CAN DRY CLEANERS IN STATES WITH CLEANUP FUNDS EVALUATE WHERE THE BEST FUNDING IS FOR THEM?

Such funds may best be used for either actual cleanup efforts, known as remediation, for which insurance dollars are generally more difficult to recover, or for sites at which such insurance dollars or other responsible parties cannot be identified. Cleanup fund dollars may also provide seed money to perform any insurance archaeology or pay for other efforts that can identify where dollars for cleanup may be found. The bottom line is that a fund with enough money to pay for cleanups is a good thing. However, the problem is that most states do not have enough money in the fund to cover the necessary cleanups at this time.

6. WHAT WOULD BE AN IDEAL SITUATION FOR A DRY CLEANER WHO HAS ACCESS TO A STATE CLEAN-UP FUND AND INSURANCE COVERAGE?

An ideal situation is a fund that allows dry cleaners to pursue any and all avenues to bring dollars to the table and be available as a safety net for cleaners that do not have other avenues to pursue. Ideally the fund would be used to seed initial efforts, such as finding insurance dollars to bring to the table. We have had situations where the historical insurance paid the deductible required by the fund, the fund monies kicked in and the insurance addressed dollars above the fund limit.

See how one dry cleaner’s state funding challenges were solved by insurance archeology

7. WHY SHOULD DRY CLEANERS FEEL CONFIDENT ABOUT THEIR ABILITY TO FIND HELP WITH CLEAN-UP WHEN STATE CLEANUP FUNDS ARE NOT AVAILABLE OR ARE NOT FINANCIALLY ADEQUATE?

Our experience has been that dry cleaners, particularly dry cleaners that have been at their site since at least the early 1980’s, have an excellent opportunity to get the site investigation and remediation paid for by either their old insurance companies or other responsible parties. We have even conducted individual site investigations costing over $2,000,000 at no cost to individual dry cleaners by using liability insurance policies from the 1980’s to pay for contamination problems. After successfully working on over 200 dry cleaning sites nationwide, we have helped settle over $500,000,000 in insurance coverage claims, including individual projects in excess of $44,000,000. There’s no reason why contamination has to destroy the value of a dry cleaning business when there are viable solutions available.

To find out if historical insurance assets are an available funding avenue for you, contact us for a confidential consultation.

Dru Carlisle, Director of Drycleaner Accounts

Dru Carlisle, Director of Drycleaner Accounts

For over 10 years, Dru has helped numerous business and property owners facing regulatory action, navigate and manage their environmental liability. Dru has vast experience in assisting dry cleaners in securing funding for their environmental cleanups through historical insurance policies. Dru is a member of numerous drycleaning associations in addition to serving on the Midwest Drycleaning and Laundry Institute (MWDLI) advisory council and on the Drycleaning & Laundry Institute Board (DLI) as an Allied Trade District Committee Member.

Jeff Carnahan, President at EnviroForensics

Jeff Carnahan, President at EnviroForensics Richard F. Ehrenreich, F- CBI, CED, SBA is the Managing Member and Principle Consultant/Broker with Ehrenreich & Associates, LLC. Richard is a recognize national expert in the Exit Strategy and Sale of Privates Owned Businesses. Richard has served in leadership roles for multiple dry cleaning associations. He is the third generation of family businesses that serve the Dry cleaning Industry for over 60 years. Over the past 15-years, Richard has completed over 800-unit evaluations, plus various legal and financial issues.

Richard F. Ehrenreich, F- CBI, CED, SBA is the Managing Member and Principle Consultant/Broker with Ehrenreich & Associates, LLC. Richard is a recognize national expert in the Exit Strategy and Sale of Privates Owned Businesses. Richard has served in leadership roles for multiple dry cleaning associations. He is the third generation of family businesses that serve the Dry cleaning Industry for over 60 years. Over the past 15-years, Richard has completed over 800-unit evaluations, plus various legal and financial issues.

Mr. R. Scott Powell is a Senior Project Manager with over 20 years of environmental consulting experience. Mr. Powell’s expertise covers a wide variety of projects ranging from due diligence, LUST/petroleum, hazardous material remediation, asbestos, lead-based paint, remedial actions, to remedial systems. He manages complex relationships fostering the cohesive involvement of several parties on multiple sites with co-mingled contaminant plumes requiring the implementation of remedial solutions for chlorinated solvents, hazardous materials, and petroleum hydrocarbon impacts. He has extensive experience with environmental regulatory compliance, including Clean Water Act (CWA), Comprehensive Environmental Response Compensation Liability Act (CERCLA), Resource Conservation Recovery Act (RCRA), Superfund Amendments and Reauthorization Act (SARA), and Toxic Substance Control Act (TSCA). Mr. Powell manages negotiations with state and federal regulatory agencies, provides litigation support in matters concerning environmental issues, and acts as a third-party reviewer of work performed by others.

Mr. R. Scott Powell is a Senior Project Manager with over 20 years of environmental consulting experience. Mr. Powell’s expertise covers a wide variety of projects ranging from due diligence, LUST/petroleum, hazardous material remediation, asbestos, lead-based paint, remedial actions, to remedial systems. He manages complex relationships fostering the cohesive involvement of several parties on multiple sites with co-mingled contaminant plumes requiring the implementation of remedial solutions for chlorinated solvents, hazardous materials, and petroleum hydrocarbon impacts. He has extensive experience with environmental regulatory compliance, including Clean Water Act (CWA), Comprehensive Environmental Response Compensation Liability Act (CERCLA), Resource Conservation Recovery Act (RCRA), Superfund Amendments and Reauthorization Act (SARA), and Toxic Substance Control Act (TSCA). Mr. Powell manages negotiations with state and federal regulatory agencies, provides litigation support in matters concerning environmental issues, and acts as a third-party reviewer of work performed by others.

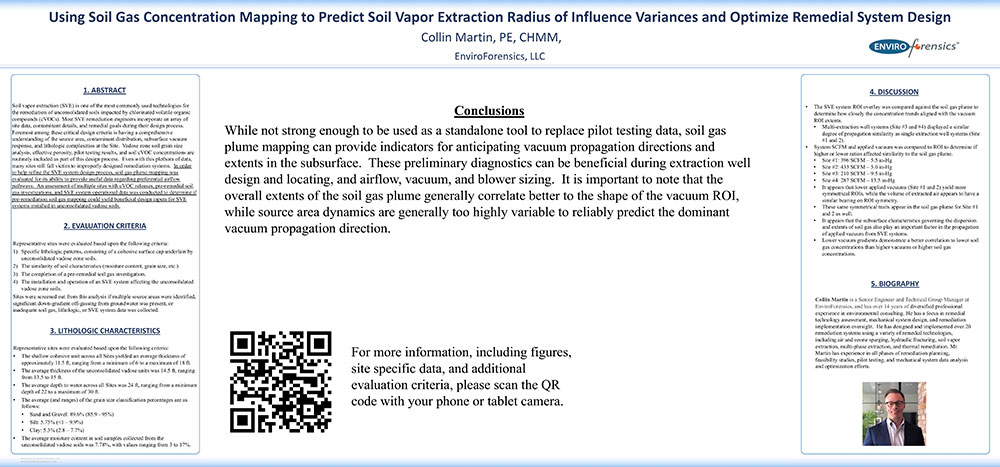

Collin Martin, PE, CHMM

Collin Martin, PE, CHMM