We are always looking for ways to better serve our clients when it comes to remediation design. After all, they rely on our expertise and command of chlorinated solvents to guide them through what could potentially be a very challenging chapter in their lives. Continually developing our abilities to think critically and make sound, confident decisions can go a long way towards choosing the best course of action. Enter the EnviroForensics Colloquium series; a series of bi-weekly discussions held among our staff to facilitate discussion and learning regarding the topic for that session.

The most recent discussion focused on remediation design, and more specifically, how our teams go about choosing one remedial technology over the other. It’s a significant subject, since the client’s wishes are heavily considered during this process.

Ranking Remediation Design Approaches

Our technical staff utilize screening matrices that help the tech team rank the remedial approaches to a given project Site. Geological conditions are typically the first elements to be taken into account. Understanding the nature of the soil and how layers of rock or sediment stack up provides the starting point in determining the technology needed to reduce contaminant concentrations. There are some remedial applications that don’t have the effectiveness in certain types of soil or geological conditions.

Contaminant Conditions

Contaminant Conditions (the nature and extent of impact) are also an important consideration during remediation design. How much is in the soil and groundwater? And where is it traveling? How fast? These answers can narrow down the options based on what technologies will be effective in treating the impact.

Land Usage

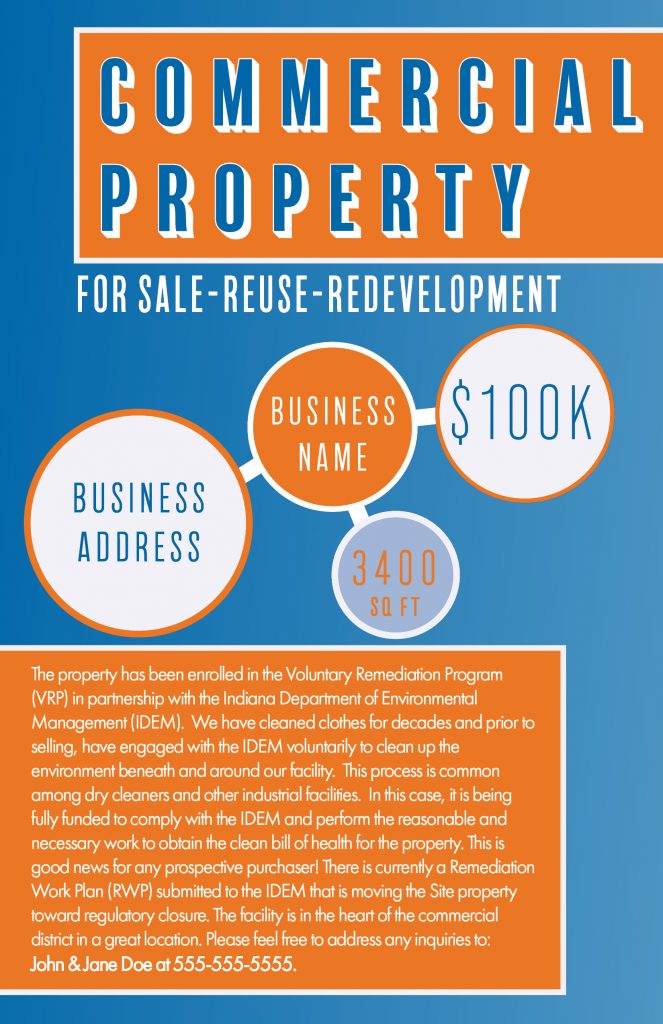

Land usage must also be assessed. What is the property’s use right now? How will it be used in the future? If it’s a business and it’s going to continue to be one, the cleanup strategy will be considerably less invasive and more labor intensive. Cleanup standards are different for residential vs commercial land use.

Cost-Effective Approaches

We prioritize cost-effectiveness. Our aim as a company is to utilize a technology that will require the fewest resources while maintaining a high level of effectiveness. Not hitting on either of these targets causes costs to rise. We focus on our client’s needs and receive a fair amount of business through word of mouth. We take great pride in that.

Timing

Which brings us to another important client –driven factor; timing. How quickly does the client need this project to be finished? And what kind of technologies can deliver the desired effects in that period of time? We want to be able to close out the project as quickly as we can: effectively remediating the contamination while keeping with the client’s needs.

Safety Concerns

Safety concerns can loom large for some technologies. A miscalculation on a subsurface injection or a slip of the wrist on the operating lever of a backhoe can pose serious threats to health and safety at the project Site. One of our core values here at EnviroForensics involves “contributing to a healthy community.” We like to practice what we preach, so if there’s a different, more safe method of remediation, we will always go in that direction.

Continual Learning

EnviroForensics provides this and many other training and learning opportunities for our staff at all levels. Chlorinated Solvents are our specialty, and activities like these allow us to retain a high level of excellence in this niche. It should be noted we operate with a “we over me” mentality often collaborating in teams to ensure the client get the best service possible, and education is key for this to happen. The colloquium series is a led discussion by our Chief Geologist or a different expert on a topic. Attendees are provided materials to read or consider prior to the meeting. We keep our eyes forward to stay on the cutting edge of technology and the most effective application of our skills.