The Clean Water Act was signed into law to maintain and protect our country’s waters, but there has never been an interpretation of the law that says it applies to groundwater, too. That is, until now. A judge in Virginia is expected to make a decision that could have widespread impact on the way utilities dispose of their coal ash after power production. Legal experts say it’s the first case of its kind to go to trial, and based on the judge’s decision, it could mean either dirtier rivers or higher electric bills in the future.

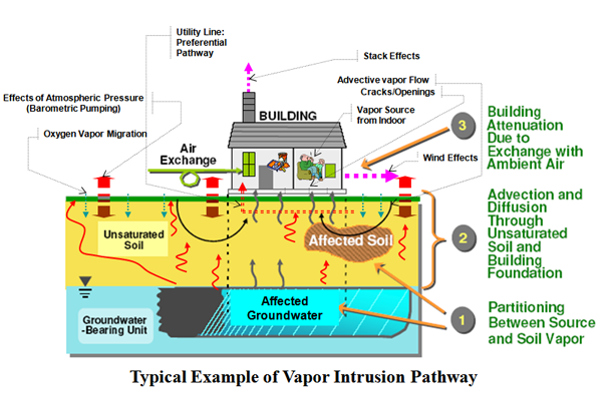

One of Dominion Virginia’s coal ash disposal sites is located along the Elizabeth River in southeast Virginia. Environmentalists assert the heavy metal-laced coal ash is leeching into the groundwater below the ash pond and finding its way into the river. The Southern Environmental Law Center filed a lawsuit against Dominion, alleging the utility was in violation of the Clean Water Act, and should be forced to move its coal ash deposits to a dry and lined facility away from waterways. Legal experts, power utilities, and environmental consultants around the country will be tuning in when the judge makes his decision, because it would provide the first precedent relating to the 2014 amendments to the Clean Water Rule as they pertain to groundwater.

Environmentalists and power companies have been debating over how to dispose coal ash for years. Environmental groups want the waste that’s currently stored near waterways to be transported to safer, leech-proof facilities, a process that a coal industry trade group indicated would cost more than a trillion dollars, and in all likelihood would increase the price of electricity service. Utilities advocate capping the already existing sites with rain proof liners, saying that would be a more fiscally pragmatic way to protect water quality, although they provide no solution for ash pond collapses like the 2014 collapse in North Carolina that resulted in millions of dollars of environmental damage. Even so, there were concerns over the impact of these possible contaminations. During arguments in the Dominion Virginia Case, there were conflicting reports on just how much arsenic from the coal ash had found its way into surface water, and if it was truly enough to pose a danger to human health. With this in mind, the presiding judge questioned the validity of spending hundreds of millions of dollars to fix the problem.

The judge has not yet said how long it will take him to rule on this case. Whichever way he rules, legal experts say the decision is likely to be appealed, and might even be brought in front of the United States Supreme Court. Environmentalists are already claiming victory, saying they hope the amount of attention put on Dominion will influence other utilities to consider changing their coal ash disposal practices.

When this case reaches its ultimate disposition, it is likely to have a significant impact not only on the storage and transport of coal ash, but the breadth of the ‘waters of the United States’ language from the Clean Water Rule, impacting not just arsenic, but the full breadth of hazardous substances and the U.S. EPA’s authority to regulate their cleanup. Considering that EnviroForensics’ day to day expertise deals heavily with the cleanup of groundwater, we will certainly be watching the case closely. An opinion finding that groundwater is not a part of the Waters of the United States under the new Clean Water Rule could conceivably render the regulatory framework that keeps our well-derived water clean ineffectual until new rules in line with the court’s decision could be drafted. Either way, a decision is forthcoming, and we will keep you posted on it when it happens. Stay tuned!