REGARDLESS OF HOW CONTAMINATION CAME TO BE OR CAME TO BE DISCOVERED AT YOUR DRY CLEANING SITE, THE END GAME IS TO CLEAN UP THE PROPERTY WITH THE RIGHT TOOLS AND MOVE ON WITH YOUR LIFE. HERE WE DISCUSS THE REMEDIATION OPTIONS AVAILABLE FOR DRY CLEANERS.

BY: JEFF CARNAHAN

Some questions you may consider when faced with environmental cleanup include “What does the cleanup process look like?”, “How long does it take?”, “How much does it cost?”, “What kind of inconvenience will you or your tenant have to endure during the process?”. There are many options available for use during site remediation at dry cleaning sites, but several factors need to be considered to determine which of them is best, including:

- Types of contaminants, like perc, that need to be addressed

- Extent of the contamination like soil impacts and/or soil, groundwater and vapor

- Property-specific geologic conditions like clay or sand

- Naturally occurring geochemical conditions

- Timing limitations

- Cost limitations

- Property usage limitations like building occupancy

Once a clear picture has been developed regarding your specific needs, then your environmental consultant can put together a remediation plan with the various tools from their tool belt to get the job done. Each technical component of the cleanup approach will have limitations, based upon your site needs, so putting together the right tools requires some creativity and a substantial amount of attention to your business needs. If this all goes smoothly, you can get your regulatory closure and peace of mind knowing that this challenge is now in the past.

THE CLEANUP STRATEGY AND GOAL

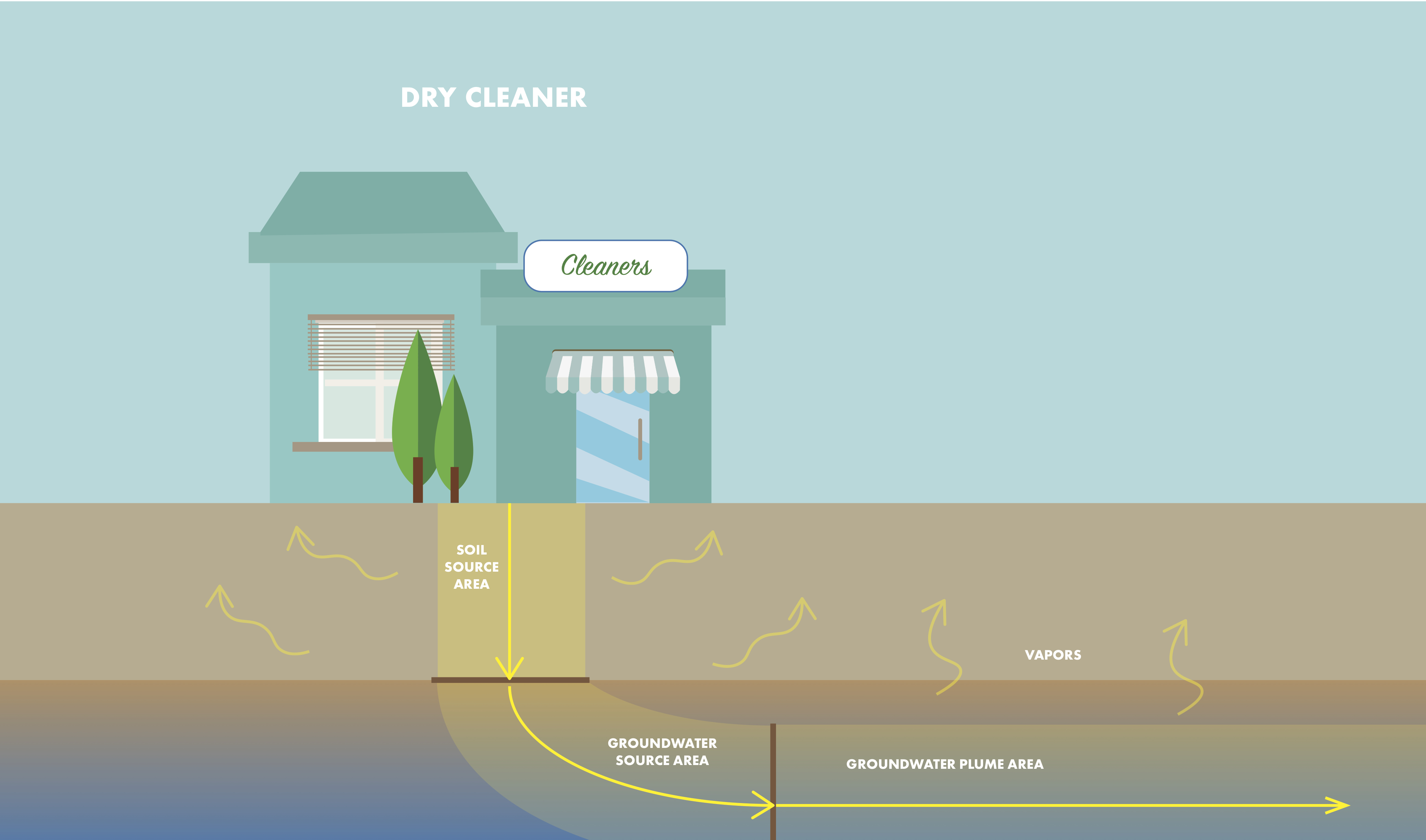

For environmental consultants to understand the right way to get contaminants out of the subsurface, they first need to learn how they got into the ground in the first place. Most of the time, one can consider a conceptual model consisting of a soil source area created by a spill. This can include leached contaminants to the groundwater, and then the impacts in groundwater have migrated to an extent and created a groundwater plume. Vapors can emanate from any portion of the impacted areas too.

Once the contaminants have moved through the subsurface to create these distinct reservoirs of impacts, environmental consultants can’t exactly reverse the process. Rather, they must address each reservoir independently, and a different cleanup technology might be necessary for each. It’s not uncommon for the soil source area and the groundwater source area to be actively remediated, while the downgradient plume is left to reduce naturally over time. Sometimes, all groundwater levels will reduce to acceptable levels just by removing a large percentage of the contaminants in the soil source area.

WHICH TOOLS (TECHNOLOGY) SHOULD BE USED?

The best way to decide which remedial technology is best used to address some or all the contaminants at your property is to look at their characteristics, capabilities, and limitations. Let’s look at some of those together, in order of the subsurface location of the contaminants.

USING EXCAVATION AND DISPOSAL FOR SOIL SOURCE AREA REMEDIATION

Excavation and Disposal is a common approach to remove contamination from soils above the water table in areas that have access to the ground surface. This doesn’t mean that excavation is only good for areas beneath the parking lot, or out back. Quite often, EnviroForensicsperforms surgical source area excavation activities inside buildings with active dry cleaning operations. It can be tricky, and planning is needed, both for the environmental work and to make sure that your operations aren’t interrupted, but it can be done. That being said, it is certainly easier to perform a significant excavation outside of buildings, and if the extent of impacts is limited and well-defined, it is often the fastest and easiest way to definitively remove a large amount of impacted materials from your property. Even for a sizeable excavation, we are talking about days or weeks, rather than months or years to achieve the objectives of the soil source area cleanup objectives.

USING SOIL VAPOR EXTRACTION FOR SOIL SOURCE AREA REMEDIATION

Another soil source area cleanup technology that is popular at dry cleaning properties is Soil Vapor Extraction (SVE). This technology takes advantage of the volatile properties of dry cleaning solvents and, as the name suggests. A SVE system includes a series of screened pipes that are installed in the soil, which are all piped together and connected to a high-volume, specially designed and manufactured industrial fan, or blower. When activated, air is drawn through the treatment area and extracted through the screened pipes.

The contamination in the soil transfers from within the soil itself to the circulating subsurface air, which then travels through the system to a discharge stack. Once passed into the air and exposed to sunlight, the volatile compounds are destroyed. The result is clean soil. SVE systems can be installed both inside and outside of existing buildings, and new buildings can even be constructed over the top of these systems, so access is not usually that big of a problem.

The potential usefulness of SVE depends mostly on the characteristics of the soil. Tighter materials like clay are not as conducive to SVE as sandier soils. Even in nice, sandy soils, the process can take a year or two following the installation and startup of the system. The blowers can be a little noisy, but in most situations, that can be taken care of pretty easily. SVE is a nice option because it also takes care of vapor intrusion problems at the same time it is cleaning up due to the negative pressure created in the subsurface during its operation.

USING THERMAL TREATMENTS FOR SOIL SOURCE AREA REMEDIATION

Another option for addressing contamination in the soil source area is the use of a Thermal Treatment technology. There are several alternatives available, but they all include the primary approach of heating up the subsurface to a temperature high enough to increase the volatility of the contaminant, and then capture the resulting vapors using an SVE system as described above. Thermal treatment has several advantages, such as being relatively quick and very reliable. It makes even more sense when used to treat the groundwater beneath the soil source area at the same time. The main drawback is the price because it’s usually a more costly options since so much electricity is used to create the high subsurface temperatures. Thermal is a great option if you absolutely must have a very clean site, have less than a year to do it, and you can avoid active usage of the area during the duration of the treatment. It’s possible to conduct thermal beneath buildings, but it is not usually feasible. EnviroForensics has used thermal at a dry cleaner site and the cleanup results were awesome. I wish we could use it more often.

USING IN-SITU FOR GROUNDWATER SOURCE AREA REMEDIATION

Directly beneath the soil source area, the area of highest groundwater impacts is usually found, which is referred to as the groundwater source area. When the remediation strategy involves the removal or destruction of contamination from the groundwater source area, there are many options to choose from.

In fact, the treatment of groundwater contamination is one of the most active areas of research and development in the environmental industry. Twenty years ago, it was common to install systems to pump out the contaminated groundwater, treat it at the surface, and then discharge it to a sewer. That practice didn’t really work very well, however nowadays most groundwater treatment actually takes place in the ground. When a treatment is applied in place, it is called an in-situ treatment.

In-situ Chemical Oxidation (ISCO) and In-situ Chemical Reduction (ISCR) are processes wherein chemicals are injected directly into the groundwater treatment area through drill-rods or temporary wells, where the chemical reacts with, and destroys the contaminant. It is a fairly quick process, which is good, but that also means that the effective life of the chemical injected is short.

One of the main limitations of any in-situ injection approach is that the desired chemical reaction is only able to happen precisely in the area where it is injected. You must have enough injection points to actually disperse the chemical where it needs to be. Subsurface intricacies in the geologic conditions tend to hijack your injection strategy, thereby leaving areas inadvertently untreated. This can result in disappointing initial results that lead to additional injection events, which is why second and even third injection events are often planned for the cleanup strategy. There are great products available for in-situ application in groundwater, and we have had a great deal of success using them, but you just have to manage expectations and hedge your bets.

USING IN-SITU FOR GROUNDWATER PLUME AREA REMEDIATION

The area of contamination downgradient of the source areas typically carry the lowest relative concentrations, but they may still be quite high. The Downgradient Groundwater Plume is the most likely to cross property boundaries into locations that aren’t under your control, leading to the need for an active clean up even though the contaminant levels may be low. Also, it may be necessary to lessen the risk that an impacted adjacent property owner decides to sue you. The in-situ injections I mentioned previously are a great way to treat this section of impacts since the extent of the plume may be quite large and the volume of chemicals necessary to destroy the lower levels of contaminants may not be large.

Sometimes, the contaminant concentrations in the downgradient plume are low enough that the plume starts to shrink once active remediation is conducted in the source areas. This is actually what we hope for most of the time. In this scenario, the concentrations in the downgradient plume just needs to be monitored on a periodic basis to ensure that they continue to decline. When this strategy is undertaken, it is called Monitored Attenuation. Obviously, this is a pretty cost effective and non-invasive approach, but the timeframe can get pretty long. If monitored attenuation is attempted without aggressive cleanup in the source areas, it can go on for decades and end up costing more than active remediation.

WHEN IT COMES TO DESIGNING AN APPROPRIATE REMEDIATION FOR YOUR DRY CLEANING PROPERTY, CONSULTANTS HAVE A LARGE TOOL BELT. THERE DOES NEED TO BE A VERY FRANK, FACE-TO-FACE DISCUSSION ABOUT THE PRACTICAL AND REASONABLE IMPLICATIONS OF REMEDIAL IMPLEMENTATION, HOWEVER. DON’T BE AFRAID TO ASK YOUR CONSULTANT ABOUT THE STRATEGY TO MAKE SURE THAT YOU ARE GETTING THE CLEANUP YOU WANT.

Contact EnviroForensics, the dry cleaning industry’s most trusted environmental consultant.

As seen in Cleaner & Launderer

Jeff Carnahan, President at EnviroForensics

Jeff Carnahan, President at EnviroForensics

Jeff Carnahan, LPG, has 20+ years of environmental consulting and remediation experience. His technical expertise focuses on the investigation and interpretation of subsurface releases of hazardous substances for the purpose of evaluating and controlling the risk and cost implications. He has focused on being a partner with the dry cleaning industry for the past decade, and he’s a frequent contributor to the national dry cleaning publication Cleaner & Launderer. He is an industry leader in understanding that environmental risk includes not only cleanup costs, but also known and unknown third-party liability.